Spills are a chronic problem in factories that can lead to major losses in productivity, safety and ultimately profits. Therefore, there must be an effective and efficient solution. One of the best solutions for fixing leaks is to use waterproof tape, such as butyl tape.

Butyl rubber is a synthetic rubber that is highly flexible, durable, and resistant to sunlight, weather, and chemicals. It is an ideal material for making waterproof tape, especially for outdoor and industrial use. Butyl tape has high adhesive strength and can be firmly bonded to different substrates, including wood, metal, plastic and concrete.

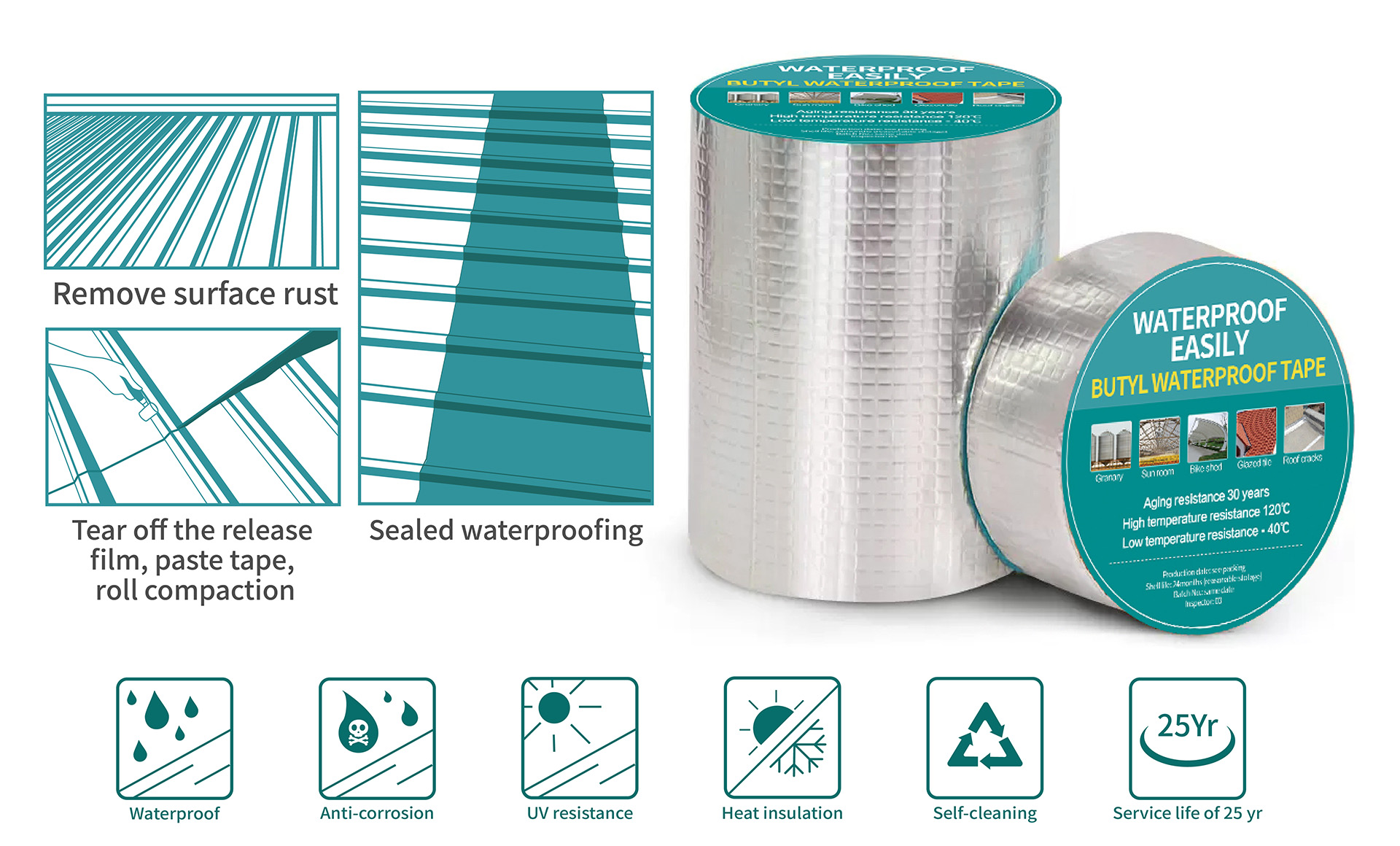

Butyl waterproofing tape is known for its ability to provide a watertight seal and prevent leaks from a variety of sources such as pipes, roofs, gutters, windows and doors. It is widely used in industries such as construction, plumbing, automotive and aerospace. Butyl tape is easy to apply, doesn’t require any special tools, and is cost-effective.

In the plant leakage project, butyl rubber waterproof tape is used to repair the leakage of water pipelines, chemical tanks and industrial equipment. Butyl tape is also used to seal joints and connections in various plant components, including pipes, valves and flanges. This tape is especially useful for repairing leaks in hard-to-reach areas, saving time, money and effort.

To sum up, it is essential to use waterproof tapes such as butyl tapes in plant leakage projects. Butyl rubber waterproof tape provides an efficient and effective solution for leak trapping, heat insulation, and sound insulation. Butyl tape is easy to apply, durable and resistant to weather, UV radiation and chemicals. It is a cost-effective and reliable solution for plants that need to prevent or repair leaks.

Usage: base cleaning → node consolidation → spread special waterproof tape → edge closing treatment.

Post time: Jun-26-2023