Tel : +8615996592590

Products

High voltage self fusing silicone rubber repair tape

Description

Silicone rubber tape is an excellent insulating and sealing material that is highly versatile . It is made using high-quality silicone rubber that has been imported from top-quality suppliers. The material is then processed using special technology to ensure that it has the right properties to meet your application requirements.

One of the main features of silicone rubber tape is its high temperature resistance. It can withstand temperatures ranging from -60℃ to 200℃, making it ideal for use in environments that require a high degree of thermal stability. Additionally, it is also highly impact-resistant and can absorb shocks and vibrations, making it suitable for use in harsh environments.

The high voltage penetration of silicone rubber tape makes it an ideal choice for use in electrical applications. It can withstand voltages of up to 30kV/mm, making it suitable for use in electrical power distribution systems, motors, transformers, and other applications.

In addition to its insulating properties, silicone rubber tape is also highly waterproof, making it an excellent choice for sealing electrical components and other items that need protection from moisture. It provides a firm seal that prevents water from penetrating into the interior of the item, thus protecting it from damage.

Specification

|

Model |

Thickness(mm) |

Width(cm) |

Length(m/roll) |

|||||

|

JL-03 |

0.3 |

20 |

25 |

30 |

|

|

|

30 |

|

JL-03 |

0.5 |

20 |

25 |

30 |

40 |

45 |

50 |

20 |

|

JL-03 |

0.8 |

20 |

25 |

30 |

40 |

45 |

50 |

5 |

|

JL-03 |

1.0 |

20 |

25 |

30 |

40 |

45 |

50 |

5 |

Tech Specs

|

Experimental project |

Require |

Actual value |

Test Methods |

|

tensile strength |

>2.5Mpa |

3.2 |

GB/T1040 |

|

Tensile elongation |

>500% |

660 |

GB/T1040 |

|

Heat resistance: 100°C/168h |

No cracking, no deformation, no visible bubbles |

pass |

GB/T7141 |

|

Self-adhesive (24 hours in room temperature water) |

Not loose, no water between layers |

Pass |

Pass |

|

Power frequency dielectric strength |

>30kV/mm |

35 |

GB/T1408 |

|

Volume resistivity |

>1X1014Ω·cm |

4.8X1014 |

GB/T1410 |

|

dielectric loss tangent |

<0.035 |

0.018 |

GB/T3048.11 |

|

Dielectric coefficient |

<3.5 |

3.1 |

GB/T1409 |

|

Electric carbon mark index (inclined plate method) |

>3.5kV |

3.6 |

GB/T6553 |

Instructions

Peel off the isolation film and clean the surface of the wrapped piece before bandaging. When bandaging, wrap the silicone rubber self-adhesive tape around the bandaged piece. When wrapping, be sure to tighten the adhesive tape while wrapping so that it has more than 30% of the adhesive tape. elongation, and press the adhesive tape with your fingers at the same time to make the two layers of adhesive tape fit tightly together. Leave it at room temperature for more than 12 hours or bake it at 100~120°C for 2 hours to make it become A solid, tight whole that can no longer be torn or peeled apart.

Company information

Nantong J&L New Material Technology Co., Ltd. is professional manufactureres of butyl sealing tape, butyl rubber tape, butyl sealant, butyl sound deadening, butyl waterproof membrane, vacuum consumables in China.

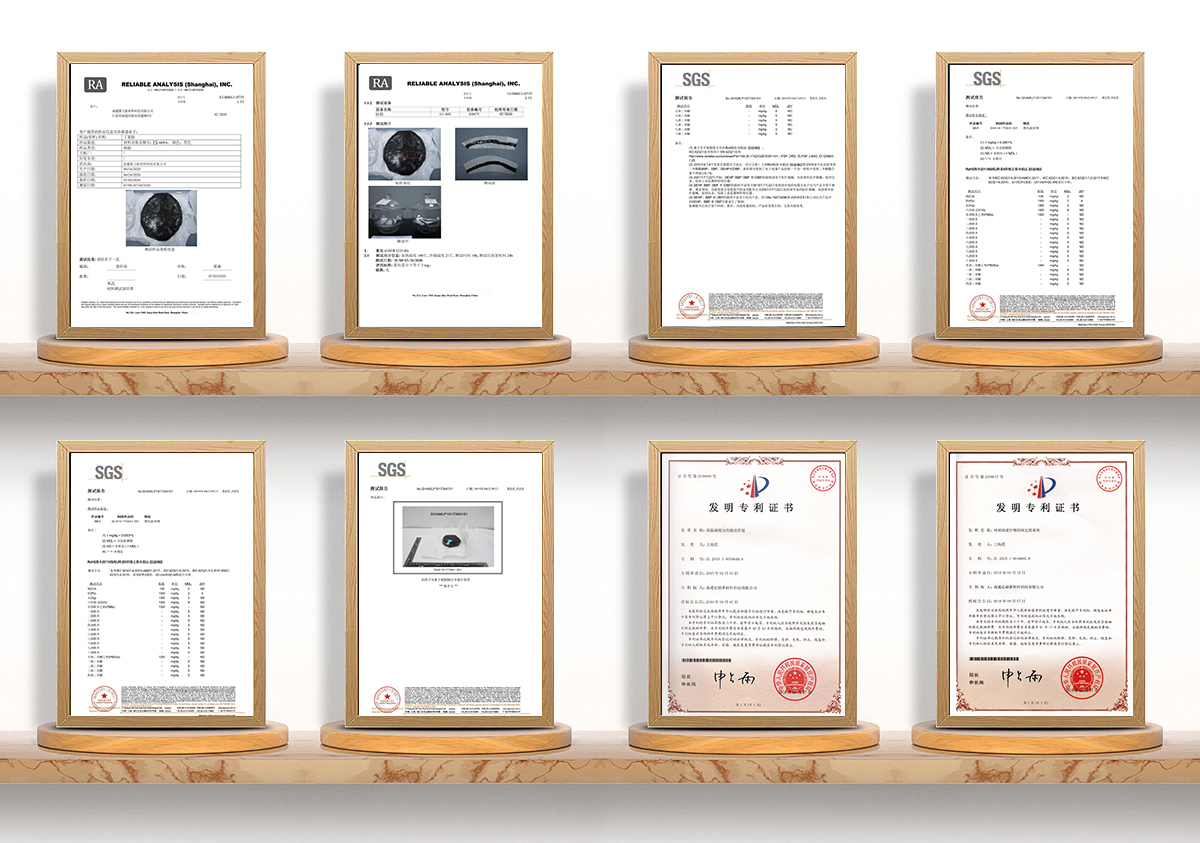

Certificate

Packaging&Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q:What is your terms of packing?

A:Generally,we pack our goods in box.If you have legally registered patent, we can pack the goods in your branded boxes after getting your authori- zation letters.

Q: How long is your delivery time?

A:If order quantity is small,then 7-10 days,Large quantity order 25-30 days.

Q:Can you provide a free sample?

A:Yes,1-2 pcs samples are free,but you pay the shipping charge.

You also can provide your DHL,TNT account number.

Q:How many workers you have?

A:We have 400 workers.

Q:How many production lines you have?

A:We have 200 production lines.