Tel : +8615996592590

Products

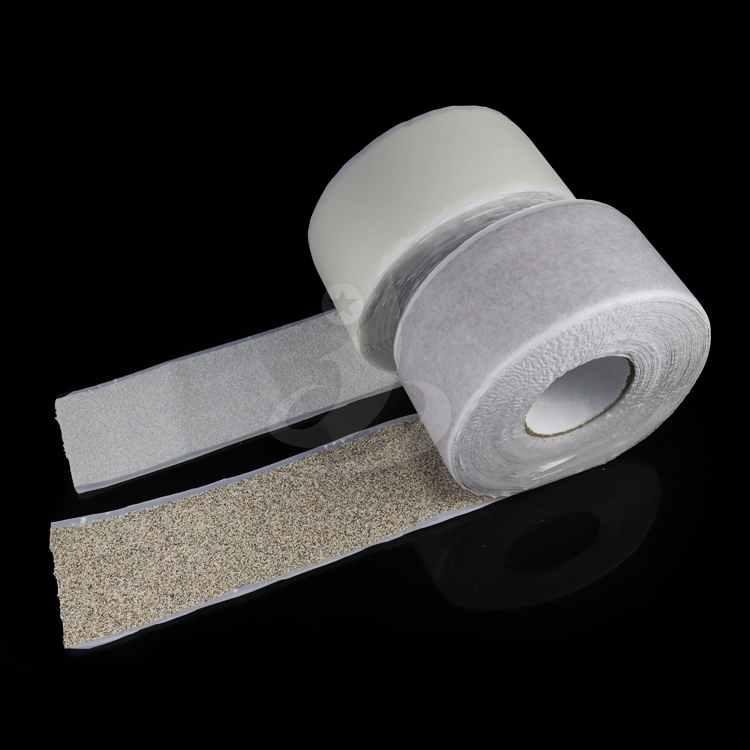

Hdpe self adhesive waterproof membrane

Description

HDPE self-adhesive waterproof membrane (non-asphalt) is a pre-paving type polymer self-adhesive waterproof membrane which has superior performance, multi-layer composite waterproof material, including a layer of high density polyethylene (HDPE) base board, a self adhesive layer which can react with HDPE base board and the sand particles or plastic film are covered. This waterproofing membrane with cast-in-place concrete by chemical cross-linking to achieve high strength bonding can completely prevent moisture penetration and leaking, without basal displacement effects. Can walking on it without using protection board if the sand covered membranes are applied and can be placed directly on the pouring skeleton reinforced after mat the holder or pad. It can effectively prevent a gas leak, gas escapes, but also have excellent resistance to puncture plant roots and backfill dicing capabilities. It has excellent weather resistance and long service life.

Product advantages

— The sand cover strip can withstand a certain degree of deformation and has follow ability.

— The waterproof function layer is designed to form a composite waterproof system with the structure, improving the safety and reliability of the waterproofing project.

— It has excellent initial tack, sustained tack, and low-temperature bonding characteristics.

— Good environmental adapt ability, with performance not reduced after continuous exposure for 45 days or more.

— The coating is sprayed in a three-dimensional manner,with good adhesion to the later poured concrete.

— Designed to be dust-proof and resistant to stepping,allowing for normal human traffic during construction.

— Strong Plastic Deformation Ability, Perfectly Demonstrating The Application Performance Of High-polymer Sheets.

— The micro-design system (technology) balances the adhesive and peel-off effects ,making waterproof defects controllable.

— High-polymer sheets are flexible, dense, and have good corrosion resistance, allowing for special environmental adaptability.

— Standardized construction process, with reliable overlap fixing.

— It has soft properties and can be fitted and dense in special-shaped parts.

— It has the advantages of convenience, quickness, reduced construction cycle, accurate dosage and reduced waste.

Application

— The reinforced use of overlapping edges of polymer waterproof membranes and the double guarantee of overlapping and capping.

— Make a cover to strengthen the sealing process for the gap left by the docking process of the pre-paved anti-adhesive waterproofing membrane.

— Repair damaged pre-paved membranes and seal after violent punctures.

Tech Specs

| NO. | Project | Indicator | |||

| P | R | ||||

| 1 | TensileProperties | Tension ( n,50mm ) ≥ | 600 | 350 | |

| Tensile Strength Mpa ≥ | 16 | 9 | |||

| Film BreakingElongation %≥ | 400 | 300 | |||

| The Phenomenon During Stretching | There is no separation between the adhesive layer and the main material | ||||

| 2 | Low Temperature Bending | Main Material-35C No Crack | Main body material and adhesive layer -35℃, no cracks | ||

| 3 | Low Temperature Flexibility | Adhesive Layer-25C,No Crack | _ | ||

| 4 | Heat Resistance | 80℃,2h No Slippage、Flow、Dripping | 100℃,2h No Slippage、Flow、Dripping | ||

| 5 | Oil Absorption/sheet ≤ | 1 | |||

| 6 | Impermeability ( 0.3 Mpa,120min ) | Impermeable | |||

| 7 | DimensionalRate% ≥ | ±1.5 | |||

| 8 | Bond Strength With The CastIn Place Concrete ( N/mm ) | Untreated ≥ | 1.5 | 0.5,Cohesion failure | |

Construction Method

Flat surface construction:

Clean The base layer → Snap lines on the base layer → Lay the pre-laid non-stick membrane → Overlap treatment → Detailed node treatment → Tie the steel bars → Pour concrete

Vertical surface construction:

Install Vertical Supports → Snap lines on the base layer → Lay the pre-laid non-stick membrane and mechanically fix it → Overlap treatment → Detailed node treatment → Tie the steel bars → Pour concrete

Tunnel roof construction:

Install Vertical Supports → Snap lines on the base layer → Lay the pre-laid non-stick membrane and mechanically fix it → Overlap treatment → Detailed node treatment → Tie the steel bars → Pour concrete

Company information

Nantong J&L New Material Technology Co., Ltd. is professional manufactureres of butyl sealing tape, butyl rubber tape, butyl sealant, butyl sound deadening, butyl waterproof membrane, vacuum consumables, in China.

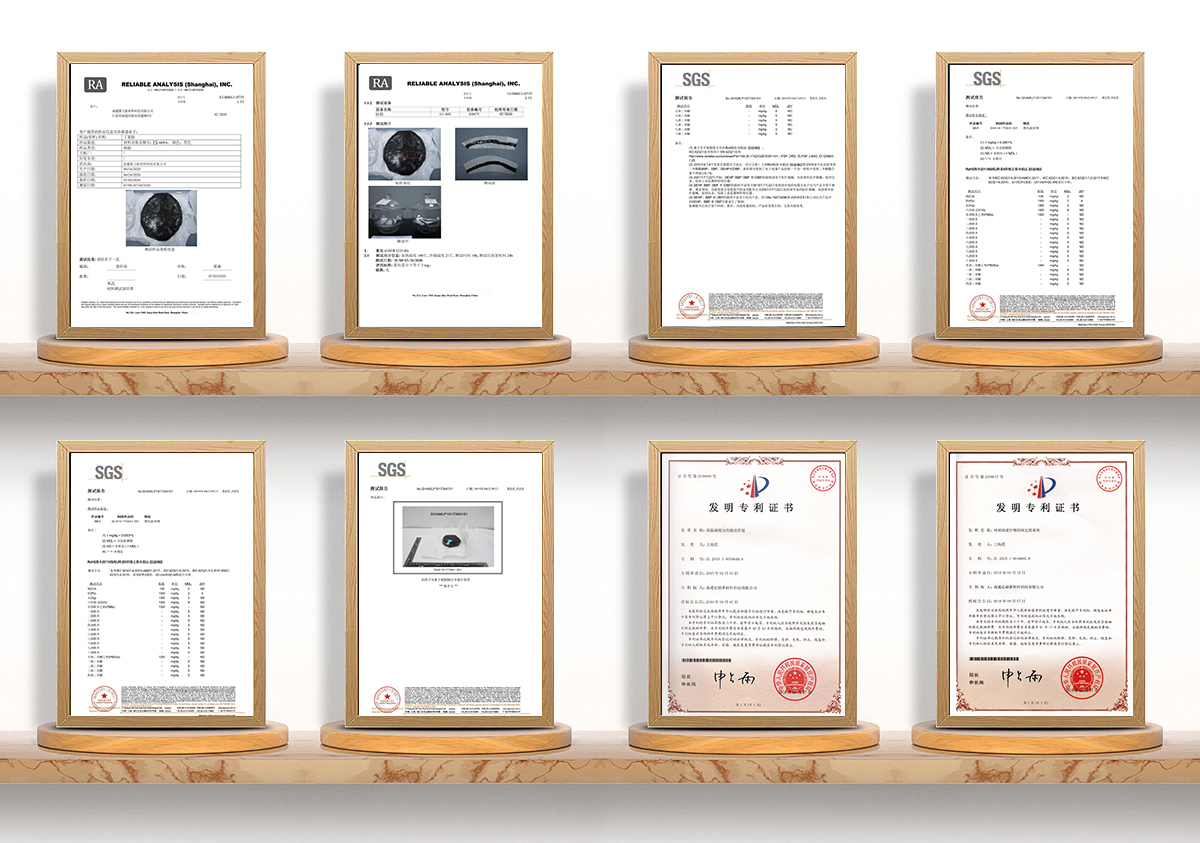

Certificate

Packaging&Shipping

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q:What is your terms of packing?

A:Generally,we pack our goods in box.If you have legally registered patent, we can pack the goods in your branded boxes after getting your authori- zation letters.

Q: How long is your delivery time?

A:If order quantity is small,then 7-10 days,Large quantity order 25-30 days.

Q:Can you provide a free sample?

A:Yes,1-2 pcs samples are free,but you pay the shipping charge.

You also can provide your DHL,TNT account number.

Q:How many workers you have?

A:We have 400 workers.

Q:How many production lines you have?

A:We have 200 production lines.